This website uses cookies to improve your experience. We'll assume you're ok with this, but you can opt-out if you wish. Read More

TL;DR

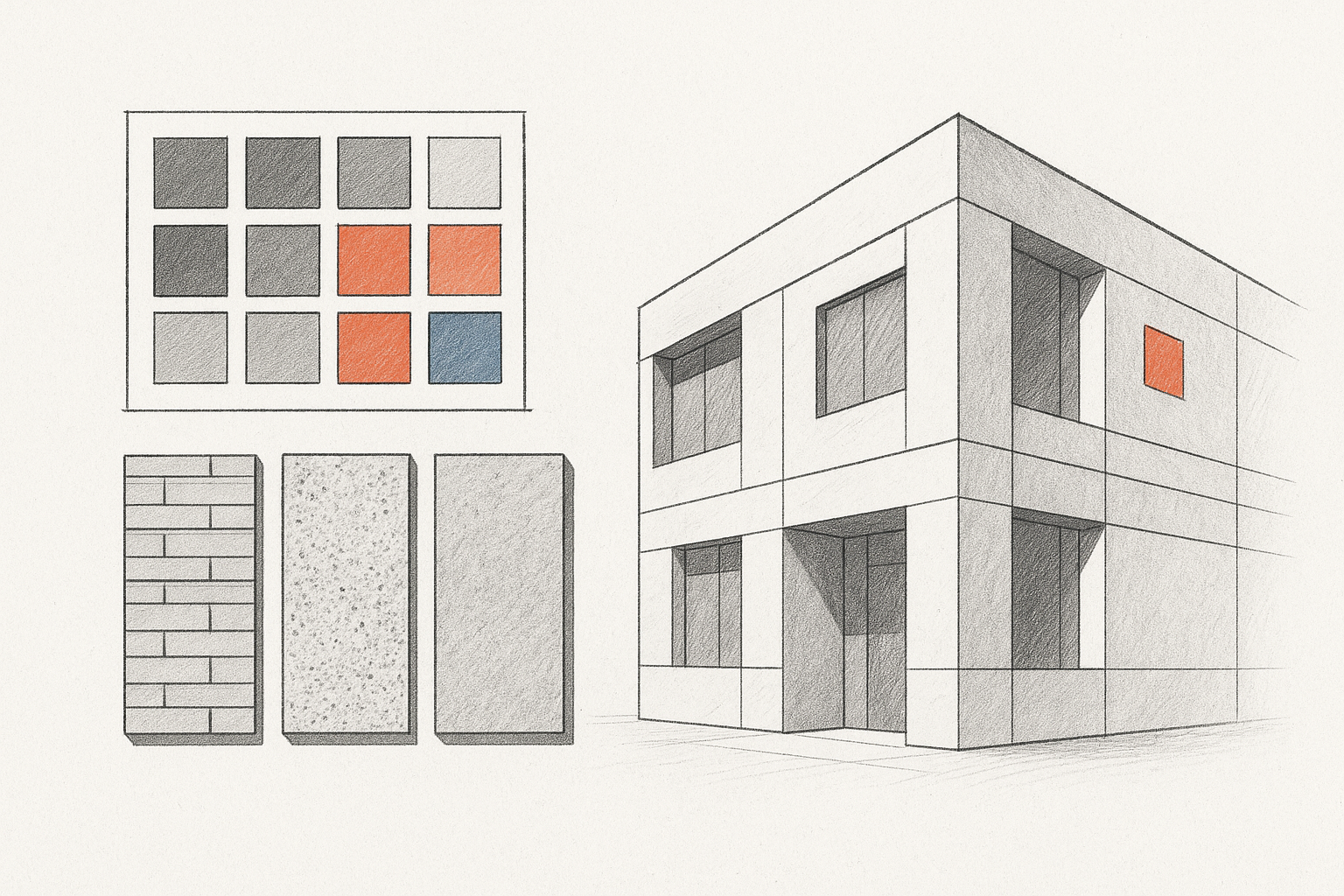

Explaining how pre-cast concrete colour is shaped by a few big levers: integral pigments (for consistent through-colour), cement choice (grey cement tends to mute tones; white cement makes colours “pop”), aggregate selection (colour, size, and exposure level change the final look), and surface finishes (acid etching, sandblasting, exposed aggregate, formliners, polishing, etc. can lighten, deepen, or add “sparkle” and texture). It stresses a practical reality check: not all hues are equally achievable (bright blues/greens and “true black” are harder and often costlier), and the only sane way to avoid disappointment is physical samples + test pieces, checked under real lighting and with the intended finish/sealer.

Understanding Pre-cast Concrete colours

Pre-cast concrete is not just about strength; it also offers an impressive palette of colours. From the classic greys to vibrant reds and blues, the options are diverse. When considering colour choices, think about integral pigments, cement types, and aggregates. A common pitfall is assuming that all colours are readily available without checking samples. For instance, mineral oxide pigments provide UV stability, ensuring that colours remain vibrant over time.

Integral colour Techniques

Integral colour is achieved by mixing pigments directly into the concrete mix. This method ensures that the colour is consistent throughout the entire piece, which is essential for large projects where uniformity is key. However, be cautious; the type of cement used can affect the final colour. If you’re using grey cement, the colour may appear muted compared to using white cement. A decision rule to keep in mind is: if you want a consistent colour across a large area, opt for integral colouring.

Concrete Color Hardener vs. Integral Colour: How to Get Coloured Concrete That Actually Matches the Sample

Coloured concrete sounds simple until you mix in pigment and end up with “muted sad grey-brown” instead of “actual black” or “bright green.” The reason is basic: your base cement, your colouring method, and your finish/sealer do most of the heavy lifting.

There are two main routes:

- Dry-shake colour hardener (surface colour): broadcast powder onto fresh concrete, then float/trowel it in.

- Integral colour (through-colour): pigment is mixed into the concrete before it’s poured/cast.

A third route exists (post-colour dyes/stains), but it behaves differently and has trade-offs.

Pros and cons of colour hardener

Pros

- Stronger, more wear-resistant surface (acts like a toughened cap on top of the slab).

- More vibrant colour options than integral colour alone (including blues/greens in many product lines).

- Affordable per m²/ft² compared to some “exotic pigment + white cement” integral mixes.

- Can reduce colour-related call-backs because you control saturation at the surface (instead of relying entirely on the ready-mix plant’s batching).

Cons

- Mostly for horizontal surfaces (verticals need special handling).

- Messy and labour-intensive (powder goes airborne; you’ll be masking everything nearby).

- Risk of surface crusting in hot/windy conditions if moisture flashes off too fast.

- If the slab chips deeply, you can reveal uncoloured concrete beneath (because the colour is surface-concentrated).

Surface Finishes for Precast Concrete Cladding Panels

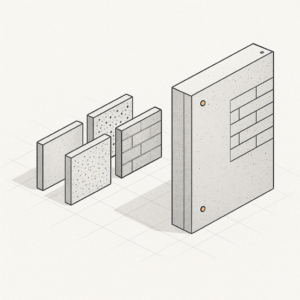

The surface finish of pre-cast concrete can dramatically enhance its aesthetic appeal. Options include finishes that replicate brick or stone, as well as various colours and tints. Techniques like formliners and abrasive blasting can create unique textures. If you desire a more textured look, consider acid etching, which adds sparkle and depth. The key is to choose a finish based on the desired texture and depth of the project. For example, a project aiming for a rustic look might benefit from a stone replication finish.

The Role of Aggregates in Colour

Aggregates are a key ingredient in determining the final bespoke concrete colour and aesthetic of pre-cast concrete. By carefully selecting coloured sands or crushed stones, you can achieve a wide spectrum of shades, from subtle, earthy tones to more vibrant hues. For instance, aggregates such as granite, quartz, or marble can provide natural, speckled tones that blend seamlessly into an environment or create a luxurious finish. Using recycled coloured glass can introduce bright, reflective qualities for a more modern and unique appearance.

To achieve an aesthetically pleasing result, it’s crucial to consider not just the colour of the aggregate but also its size, shape, and how it will be exposed. A polished or honed finish will reveal more of the aggregate’s colour and texture, making its selection even more critical. In contrast, a light acid wash might only expose the fine aggregates (sand), subtly influencing the overall colour.

A common pitfall to avoid is assuming that all aggregates will behave the same with different cement types. The base colour of the cement – it’s standard grey or white – will significantly impact the final shade. For example, some aggregates may darken when mixed with grey cement, while others can appear much brighter and truer to their original colour when combined with white cement. Therefore, it is essential to create small test samples with different aggregate-cement combinations to accurately predict the final appearance and ensure it meets your design expectations.

Cement Types and Their Impact

The type of cement you select can significantly impact the colour of your pre-cast concrete. White cement, for example, is ideal for achieving lighter and brighter colours, while grey cement is often used for more traditional hues. If you are aiming for a specific colour outcome, make sure to match the cement type accordingly. However, be aware that white cement can be more expensive than its grey counterpart. A good rule of thumb is: if vibrant colours are essential for your project, investing in white cement might be worth the cost.

Achieving Different Looks with Finishes

There are several finishes available that can help you achieve unique looks with your pre-cast concrete. Techniques such as sandblasting, acid etching, and exposed aggregate can all alter the appearance. Sandblasting, for instance, lightens and frosts surfaces, creating a visually appealing texture. When choosing a finish, consider how it will affect the perceived colour and texture of the concrete. If you desire a more refined look, acid etching might be the best option, while exposed aggregate can provide a more rugged appearance.

Key Considerations for colour Selection

Selecting the right colour for your pre-cast concrete project involves careful consideration. Always request physical samples for accurate matching, as colours can appear differently on screens. A common pitfall is relying too heavily on digital representations, which can mislead. Always evaluate colour under various lighting conditions to ensure it meets your expectations. This step is crucial for achieving the desired outcome in your designs.

The “why isn’t my colour bright?” reality check

A lot of pigments used day-to-day are iron oxides, which naturally live in the world of browns, tans, reds, and greys. If you want bright blues/greens/true whites, you’re often talking about different chemistry (and cost), plus a white cement base so the colour can actually pop.

Practical rules people run into on site:

- White Portland cement makes colours “pop,” but it’s harder to find and more expensive than standard grey cement.

- Starting with grey cement means your colour is always fighting a darker “base canvas,” so the final tone is often muted vs the colour chart.

- “True black” is notoriously difficult with standard oxide pigments; many blacks lean purple-ish.

Using hardeners and integral colour together

Often the best-looking work is layered:

Integral bespoke concrete colour sets the overall base tone (and protects you from chips showing plain concrete).

Colour hardener boosts surface richness and wear resistance.

Then you can add surface treatments for variation (stains/dyes) and lock it in with the right sealer.

A very normal “real world” combo for vivid results is:

- White cement (if chasing bright colour) + integral pigment, then

- Dry-shake hardener for punch, then

- A sealer to deepen/enhance tone.

Common Colour Families in Pre-cast Concrete

When it comes to pre-cast concrete, several popular colour families stand out, offering a range of options to suit different design styles and project themes. Neutrals like grey and charcoal are often favored for their timeless and versatile appeal, seamlessly blending into various architectural settings. Earth tones such as clay add warmth and richness, ideal for projects aiming to create a natural or earthy aesthetic. Customization opens up even more possibilities, enabling designers to explore vibrant colours that make a bold statement or add a contemporary touch.

In addition to these staples, bespoke concrete colours are becoming increasingly popular for their unique aesthetic contributions. Off-white provides a clean, minimalistic look that works well in sleek, modern designs. Green introduces a fresh, organic feel, perfect for environmentally inspired projects or spaces that aim to connect with nature. Iron grey offers a deeper, industrial elegance, often suited for urban or avant-garde architectural styles. Cream buff delivers a softer, more traditional tone, ideal for classic or rustic designs. For a bold and dramatic effect, orange and black are striking choices, with orange adding energy and black lending sophistication and depth.

When choosing a colour family for your project, it’s essential to match it to the overall theme and purpose. For example, vibrant colours like orange or green can enhance a modern, dynamic space, while neutrals such as grey, off-white, or cream buff may better complement a minimalist or traditional design. By carefully considering your project’s aesthetic goals, you can use pre-cast concrete colours to elevate the final look and feel.