Our vision

How MASS Concrete Approach Sustainability

At MASS Concrete, our core mission is to design and manufacture bespoke concrete products with the lowest achievable environmental impact, without compromising the precision, durability, and architectural finish quality demanded on high-spec projects.

Because our work is fully bespoke and made-to-order, sustainability is not an afterthought or a generic “green range.” It is engineered into the mix design, the manufacturing methodology, and the whole-life performance of each element.

Our Commitment to Sustainability

Concrete has a complicated relationship with carbon. Our approach is simple:

-

Reduce embodied carbon where technically feasible, primarily via cement reduction strategies and cement replacements.

-

Maximise resource efficiency through circular-economy thinking: reuse moulds, recycle production waste, and upcycle suitable external waste streams into new concrete mixes.

-

Design for longevity and end-of-life recoverability so environmental impact is amortised across a long service life and materials can re-enter the construction cycle.

-

Operate transparently: where we’re not certified, we state it; where we align to best-practice frameworks, we explain how.

Concrete Sustainability Facts

Recycled Content

We integrate secondary and recycled aggregates wherever performance allows, reducing demand for virgin raw materials and diverting waste from landfill. This includes recycled and waste-derived aggregates used in architectural mixes and terrazzo-style applications.

Examples demonstrated in our case studies include incorporation of:

-

Construction waste composites (brick chippings, ceramics, rubble, shells)

-

Electronic waste (recycled TV screens)

-

Industrial by-products (e.g., china clay stent)

We also maintain a very large mix-design knowledge base (2,000+ unique mixes) to tune aesthetic and performance outcomes while accommodating sustainability objectives.

Responsible Sourcing

Responsible sourcing is embedded in procurement. In practice, that means:

-

Cement sourced through an ISO 14001–accredited supplier (Tarmac), supporting environmental management discipline in the upstream supply chain.

-

Local materials where possible to minimise transport emissions (e.g., our largest sand/aggregate supplier is approximately 2 km from our factory).

-

Timber moulds aligned with the Timber Trade Federation responsible sourcing policy, supporting sustainable forestry and chain-of-custody principles.

We also align our practices with the guiding principles of BES 6001 (Responsible Sourcing), and we are working toward our BES 6001 certification and ISO 14001 certification.

Renewable Energy

Our factory operations are powered by 100% renewable electricity (renewable-backed supply). Documentation can be provided as part of prequalification and project sustainability reporting.

Waste Efficiency

We actively drive down waste through:

-

Reuse of moulds and formwork systems across production cycles.

-

A robust waste recycling programme that diverts valuable materials from landfill.

-

A circular manufacturing initiative showcased in our flood-defence work: integrating polishing pit sludge and sandblasting waste into new mixes, turning disposal liabilities into engineered inputs.

Water Conservation

Our facility operates a water recycling system designed to significantly reduce water consumption and environmental impact (closed-loop recycling for wash-down and process use, where applicable).

Product Lifecycle

We design for whole-life performance, not short-term aesthetics:

-

Durability and longevity: concrete installations often have a service life of around 100 years, spreading embodied impacts over decades.

-

Carbon sequestration via carbonation: concrete naturally absorbs CO₂ over time. Studies cited in our sustainability documentation indicate concrete can reabsorb up to ~50% of CO₂ emitted during cement production over its lifetime (with increased absorption when crushed at end-of-life due to higher exposed surface area).

-

End-of-life repurposing: our products can be crushed and reused as Type 1 / Type 2 aggregate, keeping material in productive use rather than disposal.

-

Material choices with end-of-life in mind: we no longer use recycled plastics as aggregate due to recyclability concerns at end-of-life.

Environmental Performance and Material Data

Bespoke manufacturing can make “one-size-fits-all” declarations meaningless. Because our products are made-to-order, standardised environmental datasets are not always available for each unique component. However, we provide substantiated indicators of performance and compliance where relevant.

Key indicators include:

-

BREEAM rating for GFRC: Glassfibre Reinforced Concrete (GFRC) carries a BREEAM rating of A+ in our referenced documentation.

-

VOC emissivity class: technical reporting referenced in our sustainability documentation indicates cements tested achieved A+ emissivity classification (lowest VOC emissions class).

-

Material inertness: concrete is inert, and our products have been specified on projects seeking high sustainability certifications (where finishes and sealant choices materially influence compliance outcomes).

We offer both impregnating (penetrative) and topical (surface protective) sealant systems to meet performance needs (chemical resistance, staining, slip, maintenance regime), while supporting project sustainability targets and indoor environmental quality strategies.

Why Precast Concrete & GFRC Can Reduce Whole-Life Environmental Impact

For many applications (cladding, wall panels, architectural features), offsite precast and especially GFRC provide measurable environmental and construction-efficiency advantages versus thicker traditional precast or site-cast solutions:

-

Material reduction: GFRC can be manufactured in very thin sections, typically ~15 mm skin thickness, versus ~100 mm for conventional precast panels.

-

Weight reduction: thinner sections translate to lighter components, cited as up to ~75–80% lighter than comparable precast panels, reducing transport loads and lifting energy.

-

Controlled curing and quality: factory production enables consistent curing conditions and dimensional precision, lowering rework and waste compared to weather-dependent site casting.

-

Lower site disruption: precast elements arrive install-ready, reducing onsite formwork waste and programme impacts.

-

Mechanical performance and durability: our documentation cites AR glass fibres delivering ~30% greater tensile strength than steel in the reinforced matrix, alongside low porosity and resistance to freeze-thaw and chemical exposure. These factors can reduce maintenance burden and extend service life.

-

Environmental impact: GFRC is cited as having up to ~60% lower environmental impact than traditional concrete, attributed to reduced cement content and its compatibility with recycled materials.

This matters because lifecycle impacts are not just “embodied” at practical completion. Operational and maintenance loads dominate many building carbon profiles. Our documentation notes that ~80% of a building’s CO₂ emissions can come from utilities, which elevates the importance of durability, thermal performance, and long-term behaviour.

Cement Reduction and Cement Replacement in Practice

Cement is the dominant driver of embodied CO₂ in conventional concrete. We therefore prioritise cement reduction pathways where structural and durability requirements allow, including:

-

Cement replacements such as GGBS (and, where appropriate, other SCMs like fly ash), reducing reliance on primary cement.

-

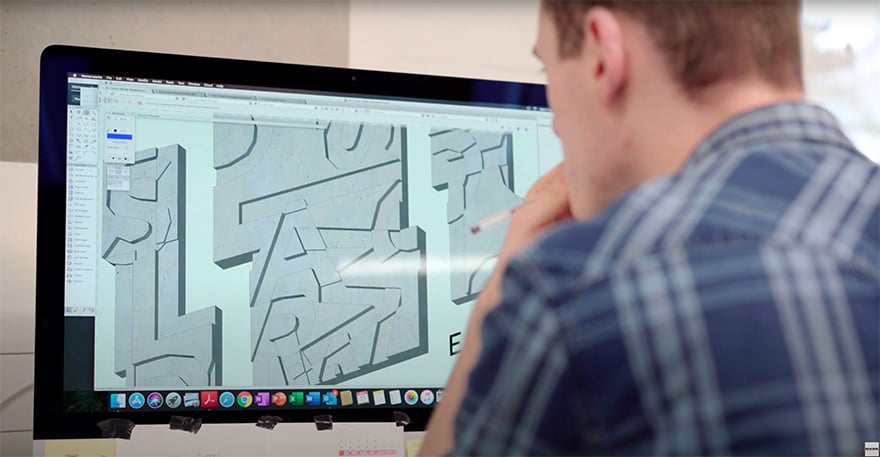

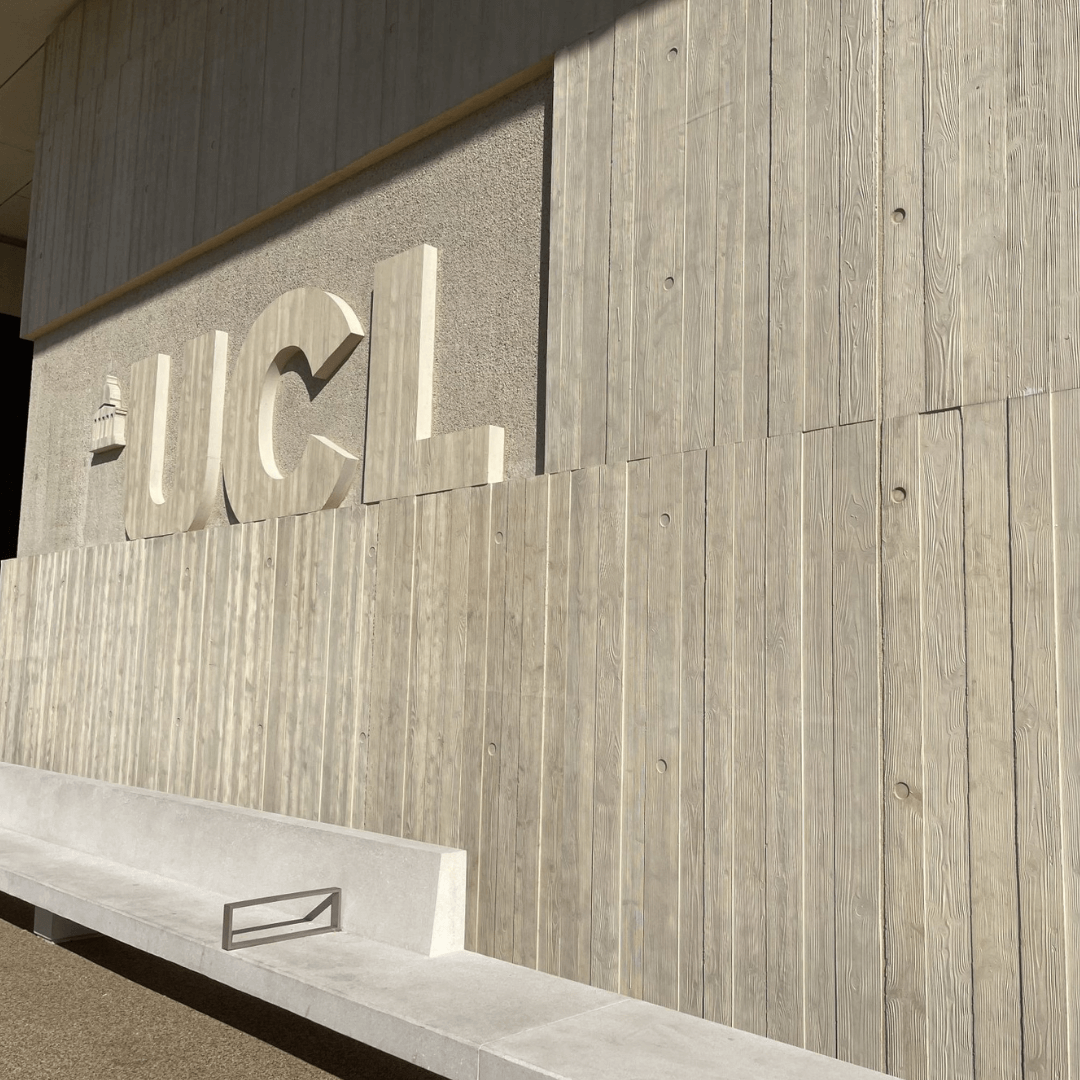

Project-specific mixes demonstrating meaningful substitution. For example, our UCL East Marshgate signage units used a blend incorporating a 40% GGBS/cement replacement, aligned to the project’s sustainability objectives.

-

In specialist applications, we have demonstrated cement reduction beyond typical SCM substitution.

In flood-defence component manufacturing, use of polishing pit sludge enabled removal of up to ~70% of cement typically required in the mix (application-specific; engineered for that product and performance requirement).

Responsible Sourcing, Governance & Compliance

We treat sustainability as a governance issue, not a brochure topic. Our sustainability documentation sets out a clear position:

-

We operate with strong governance and ethical policies, fair labour practices, and health and safety at the core of our culture.

-

We prioritise suppliers using environmental, social, and economic criteria, with an emphasis on local and trusted supply chains to reduce transport emissions and increase oversight.

-

We are transparent about certification status: not ISO 14001 certified or BES 6001 accredited, but aligned to the principles and open to future certification as our sustainability journey evolves.

-

We meet recognised prequalification standards via CHAS Elite certification, supporting SSIP / former PAS 91 and Common Assessment Standard requirements.

We also reference broader industry documentation, including an Environmental Product Declaration pathway for UK-manufactured cement produced by the MPA, supporting informed specification and reporting workflows.

Working with Project Teams

If you need a sustainability-led specification pack (mix strategy options, recycled content pathways, cement replacement ranges, sealant guidance, and end-of-life assumptions), we can provide a project-specific response aligned to your reporting framework and performance requirements.

We support specifiers, contractors, and sustainability leads with the documentation and technical collaboration required for high-performance, low-impact bespoke concrete outcomes:

-

Early-stage guidance on mix strategy, cement replacement, and recycled content suitability.

-

Mock-ups and sampling to validate finish, tone, texture, and performance criteria.

-

Advice on sealant systems (impregnating vs topical) aligned to durability, maintenance, and indoor environmental quality targets.

-

Supply-chain transparency measures, including upstream supplier environmental credentials.

Continuous Improvement of our sustainable concrete

Sustainability in concrete manufacturing is not a single solution. It is continuous optimisation across materials science, supply chain, manufacturing systems, and whole-life design. Our documented approach includes ongoing assessment, internal sustainability goals, and investment in greener concrete solutions, with openness to future responsible sourcing accreditations as the business evolves.